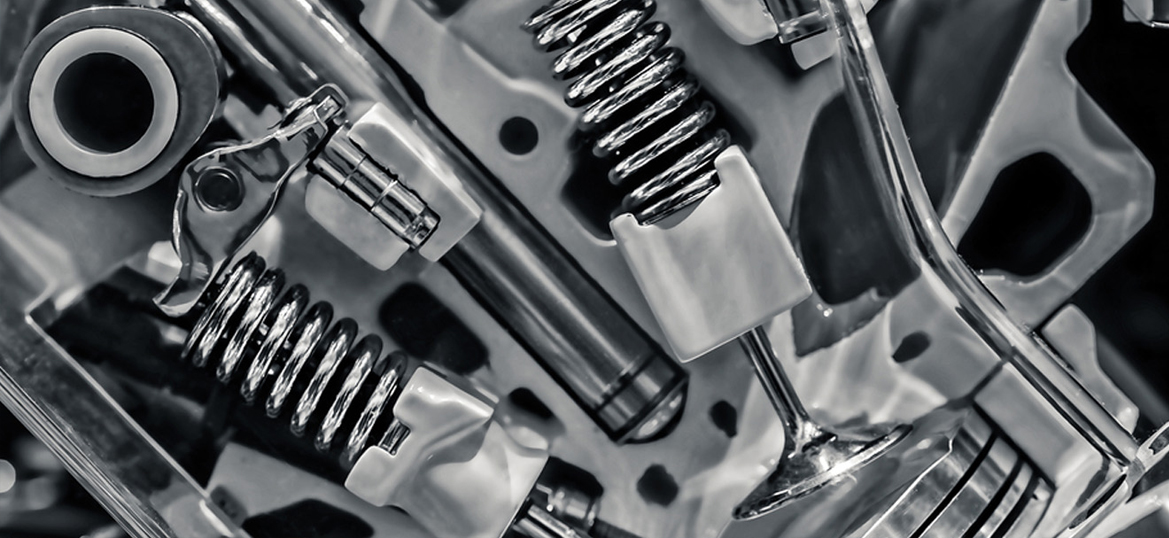

Petrol engine valves are essential components that regulate the intake of air-fuel mixtures and the expulsion of exhaust gases, significantly impacting engine performance and efficiency. Comprised of intake and exhaust valves, they ensure optimal airflow and combustion by allowing the air-fuel mixture into the combustion chamber and releasing combustion gases afterward. Designed for high RPM operation, these valves are typically lighter, promoting quicker response times. Crafted from advanced alloys that resist wear and heat, they ensure durability under intense conditions. Additionally, they work seamlessly with variable valve timing systems, enhancing fuel efficiency and reducing emissions by adapting the timing of valve openings across different engine speeds. With continuous advancements in materials and design, petrol engine valves play a vital role in the evolution of more efficient and powerful petrol engines.

Intake valves play a crucial role in the operation of petrol engines by allowing the air-fuel mixture to enter the combustion chamber. Typically larger than exhaust valves, they are designed to maximize airflow for improved engine efficiency and power output. Made from lightweight, durable materials, intake valves often feature a conical or tulip shape to enhance airflow dynamics.

Exhaust valves are equally important, responsible for releasing the combustion gases after the power stroke. These valves are designed to withstand high temperatures and pressures due to the hot gases that exit the combustion chamber. Typically made from heat-resistant alloys, exhaust valves often feature a more robust design compared to intake valves.