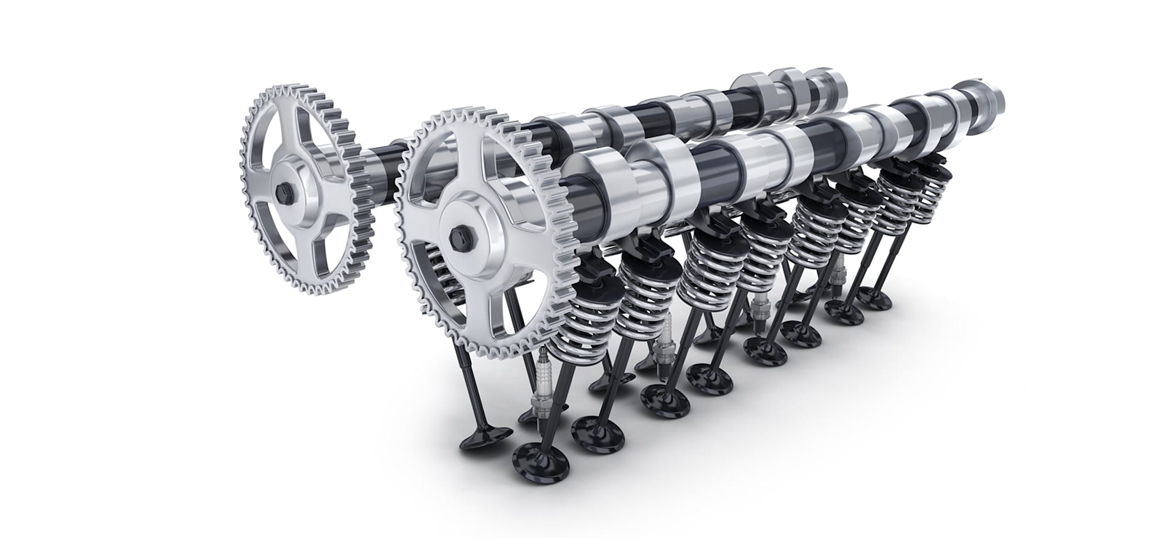

Diesel engine valves are vital components that regulate air intake and exhaust flow, playing a critical role in combustion efficiency and overall engine performance. Typically more robust than petrol engine valves, diesel valves are designed to withstand higher pressures and temperatures due to the nature of diesel combustion. Made from high-strength materials, they ensure durability and reliability under demanding conditions. Diesel valves include intake valves that allow air into the combustion chamber and exhaust valves that expel combustion gases. Their precise operation is essential for optimizing fuel efficiency, enhancing torque, and reducing emissions, making them crucial for the effective functioning of diesel engines.

Intake valves are crucial in diesel engines, as they control the flow of air entering the combustion chamber. Designed to optimize airflow, these valves are typically larger than exhaust valves to facilitate efficient air intake. They are made from durable materials to withstand the rigors of high-pressure environments.

Exhaust valves are equally important, responsible for releasing combustion gases after the power stroke. These valves are designed to endure higher temperatures and pressures compared to intake valves due to the nature of diesel combustion.